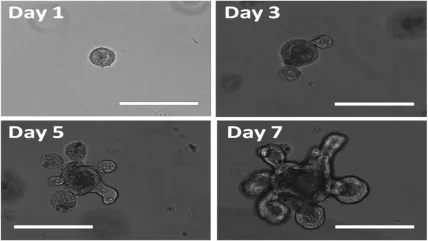

“The issue we have here on Earth,” Kevin Tabury, scientific researcher at SCK CEN, explains, “is that gravity is pulling down on all the cells”. He’s talking about biomanufacturing: the printing of 3D microtissues called organoids, which self-develop from stem cells with all the histological and functional characteristics of mature organs. On Earth, Tabury says, the pressure of gravity renders bioprinting a near-impossible task, collapsing spherical aggregates of cells into a puddle; but in low-earth orbit, scientists have discovered, microgravity promises the perfect conditions. “In microgravity, everything is floating, so you can more accurately recreate the three dimensions of the organ that you are looking for,” he says.

The thought of rocketing into space to manufacture human organs on a 3D printer sounds like the stuff of science fiction – but it is fast becoming a viable reality. Companies like Techshot, which operates its own research and manufacturing equipment on board the International Space Station (ISS) US National Laboratory, has already developed a space-based biomanufacturing platform, capable of printing with live human and animal cells. Though still at the proof-of-concept stage, there is mounting pressure to get this technology up and running by 2031: the year NASA has earmarked to send humans back to the moon.

There’s a poetic duality to this research: space makes the printing of organoids possible; and the printing of organoids makes deeper and longer space travel a more viable possibility. “On the ISS,” Tabury explains, “we are still within the protection of the Van Allen Belts, so radiation levels are relatively low. But if you take [astronauts] further – to go to the moon or to Mars – and something happens to them, they cannot just go to the hospital. The further you go from Earth, the less contact you have with people on Earth, because there is a big delay in response time; and you are limited to the amount of storage that you can take with you.” With the proper expertise on board, this biofabrication technology could, in theory, remove some of the major healthcare barriers to deep space travel.

“There’s a lot of intellectual property to be obtained by experiments in microgravity, and whoever has the best, biggest footprint in low-earth orbit, and is able to explore, is going to be able to define and protect those business models.”

William Wagner

Light years away

Right now, however, we’re a long way from printing organs that can be transplanted into a human body: Techshot and other companies are beginning to manufacture in vitro human organ models – rather than transplantable organs – which could help to advance the field of regenerative medicine back on Earth. “When we think about space travel in the long run,” Professor Lorenzo Moroni, chair of the Complex Tissue Regeneration department and vice-director of MERLN, notes, “you could imagine that a bioprinter on board a spaceship going to Mars, or bringing a first colony to the Moon, could offer first aid for travellers” – but this is a dream for the distant future.

For now, Moroni says, “biofabrication, as a broader domain of science, is one of the technology platforms used to create new regenerative medicine therapies on Earth”. In other words, these complex organoids provide a fertile testing ground – and exposing them to the conditions of space could provide new avenues for medical research. “In space,” Moroni explains, “microgravity is known to age our body. So [biomanufacturing] could be used to study ageing in an accelerated manner, compared with what happens on Earth. Similarly, cosmic radiation could be seen as an accelerated environment of ageing on Earth, when we are exposed to radiation for long [periods of] time. Hence, space could be used as an environment in which we can study ageing on a faster time scale, which would otherwise take years or even decades on Earth.”

The real barrier to getting this kind of research off the ground isn’t so much the technology itself – companies like Techshot are already providing proof of concept – but the funding. “The key thing that’s missing,” explains Professor William Wagner, director of the McGowan Institute for Regenerative Medicine, “is the viable business model that would bring in the investment. In our field, and in our institute, we discover things, we file lots of patents, but we know that to get to market it takes hundreds of millions of dollars in devices – if not billions – and that’s not going to come from a government. And its not going to come from a non-profit.”

The McGowan Institute has been at the forefront of developing technologies that address organ and tissue failure for the past 30 years – they implanted one of the first artificial hearts into a human patient as early as 1985 – and Wagner has witnessed the importance of investment first-hand. “When I started [at McGowan] in the early 90s, artificial heart technology was extremely expensive, and insurance companies wouldn’t approve it. Fast forward to now, and it’s much less expensive, and far more broadly available.”

Back in late 2019, the ISS National Laboratory contacted the McGowan Institute for help in furthering their mission to advance the nation’s leadership in commercial space. McGowan drew up plans for a three-day conference, which would bring together thought-leaders from around the country to assess the data and determine which topic areas would be most likely to translate to clinical impact – and then Covid-19 struck. “The pandemic had a very causative effect,” Wagner says, “because it cancelled that workshop and gave us the ability to stretch [discussions] out over many months and to really focus in on given topic areas and bring in a much larger group of experts.”

The next quest

The result was the publication of two white papers, with more in the pipeline, and the establishment of a four-stage roadmap to regenerative medicine biomanufacturing in space: 1. Disease modelling; 2. More effective stem cells and stem-cell-derived products; 3. Manufacturing, or 3D printing, or biomaterial, or device assembly – “its kind of a larger catch-all,” Wagner says; and 4. Automation, artificial intelligence, and machine learning. That last outcome – “getting the human out of the process as much as possible, and bringing in as much robotics and artificial intelligence as possible” – is “probably the most pronounced bottleneck,” Wagner says, but “it seems like we can do this”. And then once the data is out there, he explains, they can “really nail down what it is that a stem cell does differently, or what an organoid does differently. Then I think […] you can more convincingly answer the question of what we’re going to make of that”.

Bringing in robotics and AI to shore up the data is the missing link: if the data can be mined more effectively, then this promising research can be translated into measurable outcomes, and that’s when the necessary investment follows. And Wagner is confident that it will. “Access to space is kind of like the railroads coming through in the Western US,” he says. “It used to be that you would ride on an oxen-pulled wagon – and it was dangerous, and you’d run out of water, and it was a very long and arduous journey. And then they laid the rail tracks and suddenly everyone could get there; and then the plane and the automobile and the interstate highway system came in behind that. We’re going through this market change in accessibility now, particularly with low-earth orbit.”

Wagner’s Wild West analogy for this new frontier may have an essence of Star Trek about it, but this is not science fiction. “It’s classic macroeconomic theory,” he says. “You lower the barrier, so more things can get over, more entrepreneurial ideas can happen. Now, the most compelling business model in 2022 appears to be space tourism. There are billionaires who are willing to pay millions of dollars, even for a few minutes [in space], and if you had something like a space hotel on one of the stations, then people would pay lots of money [to stay there].”

A new frontier

The knock-on effect, Wagner explains, is that once money from space tourism begins to trickle in, a portion will be invested in scientific research. “The money that gets paid supports that infrastructure, and then that infrastructure allows us to do other things. One of the models for a private space station that’s [currently] being built,” he says, “includes space tourism, but it also has biological labs, and the vision is that companies will be interested in leasing out these laboratories to do the types of work we’ve been talking about.”

It may be many decades before we see bioprinters stowed away in a spaceship’s first aid kit – but the future of manufacturing biomaterials in microgravity for use in regenerative medicine on Earth is not only bright – it’s close. “The future of this research looks brilliant,” Moroni says. “It will be a field of exciting discoveries, where we should be able to take advantage of all the technological expertise of space experts on one side, and of the conditions that space offers to study ageing [on the other] – which is a much-needed topic of study for our ageing society.” Like Wagner, Tabury is confident that greater commercialisation will speed this process up. In the next five years, with more private companies being granted access to the ISS laboratories, we could see biomanufacturing being rolled out as an effective means of drugs testing. “Take a cancer patient for instance,” Tabury says. “We don’t know what kind of drug will be the most effective, but if we can take these cells and generate different kinds of organoid, then we could have 10 different drugs being tested at the same time.”

Wagner’s forecast is a little more conservative: “In the next decade or so” he says, “I think, absolutely, things are going to happen. There’s a lot of intellectual property to be obtained by experiments in microgravity, and whoever has the best, biggest footprint in low-earth orbit, and is able to explore, is going to be able to define and protect those business models. Its a land rush – a new frontier is opening up.”

1985

The year The McGowan Institute implanted one of the first artificial hearts into a patient.

The McGowan Institute