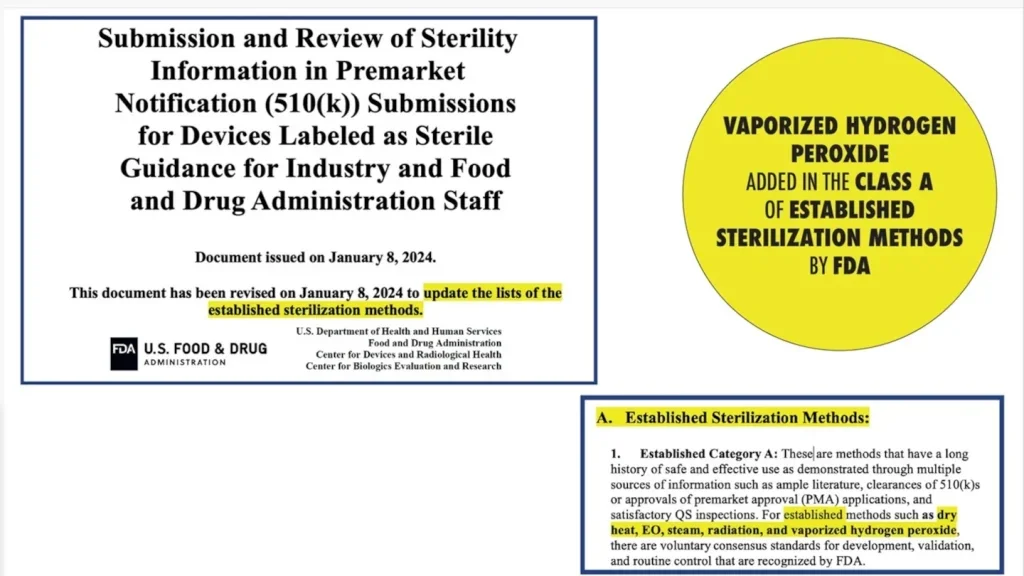

Hydrogen Peroxide: Category A sterilization method

But in a last years the technology is advanced, and now it is possible to utilize Hydrogen Peroxide not only for surfaces decontamination but for successful medical devices or other combined products sterilization.

The publication in 2022 of the ISO 22441:2022 International Standard, “Sterilization of health care products — Low temperature vaporized hydrogen peroxide — Requirements for the development, validation and routine control of a sterilization process for medical devices” was a fundamental step for the Hydrogen Peroxide to be officially recognized and its official recognition by the FDA.

With that, the Hydrogen Peroxide joined the current established Category A sterilization methods with moist heat, dry heat, Ethylene Oxide (EtO) and radiation.

It ill be important for all users to see a future harmonization withing the regulatory agencies to have this recognition more comprehensive and widely accepted.

HyPerPure® : a low temperature H202 sterilizing technology

HyPerPure® by De Lama is the new frontier of cold sterilization for solid and porous products.

Already a choice of world leading-edge Companies in Pharma and Medical Devices industries.

Fig. 2

De Lama, is leading a manufacture of autoclaves, sterilizers, washers, driers, pass-boxes, integrated clever systems and many other engineering technologies.

Thanks to many years of proven experience and excellence in the sterilization field, De Lama has developed an innovative sterilization process.

This proprietary solution operated with De Lama DLVHP/ST equipment and covered by international patent is a sterilization technology based on Hydrogen Peroxide solution vaporized by apatented vapor generator (HyPerGeneSys®) under deep vacuum and zero air.

This special generator is able to operate in a high vacuum by acting with an electromagnetic field capable of ionizing the H202 molecules in order to increase their lethal effect on microorganisms.

Vacuum system is composed by multiple step high vacuum system that allow the most effective sterilization phase with the perfect homogeneous distribution of the antimicrobial agent and the perfect nebulised H202 removal at cycle end, making the sterilization process even faster and more effective.

Especially convenient for all thermo-labile and thermo-sensitives products, HyPerPure® is effective even in the cases of most recessed cavities.

Such deep vacuum technology allows the complete gas penetration through widest variety of packaging. It is able to penetrate the packaging and to penetrate multiple layers surfaces such as Tyvek® (or medical paper), thus sterilizing the environment inside the package and the external surface of the product.

The packaged goods, are completely sterilized even into the most inner parts and holes (for objects with a complex design) once extracted by autoclave, even if the operation is realized in a non-classified area. The products preserve the sterile environment inside packaging created by sterilization process made with HyPerPure®.

This consents to eliminate the need packaging into a classified areas Class A (or B) reducing drastically the costs.

To carry out this sterilization there is no need of clean and the sterilization cycle work in an open loop, without any consumable, and grant a very high level of repeatability.

HyPerPure® features & advantages:

✅ It is a real sterilization, reaching the mandatory SAL of 10-6 satisfying the required parameters of the process validation

✅ Is the only Vaporized Hydrogen Peroxide solution with industrial possibility: the solutions include multiple and flexible models could span from 150 lts chamber up to 90 cubic meters. Sizes and shapes cloud be really infinite satisfying all possible Customer needs

✅ The bigger sizes can in this way replace other technologies and typical Ethylene Oxide (EtO) chamber size required by manufacturers..

✅ All this makes it the real GREEN alternative to Ethylene Oxide (EtO) sterilization helping to mitigate all the heavy health and risk impact

✅ It can be also a good alternative for all plastic product sensitive to gamma rays.

✅ It’s supported especially by FDA that added Vaporized Hydrogen Peroxide among the class A sterilization methods (January 2024).

✅ Optimize the overall production time, reduce time to market after the production and decrease cost of capex compare to Ethylene Oxide (EtO)

✅ It’s easy to internalize within the production plant (Not explosive, is not a pressure vessel, so no need a special certifications). This all avoids all the disadvantages and extra cost of the outsourcing sterilization & requirements for Ethylene Oxide (EtO) or Gamma plants.

✅ The average process time spans from 3 to 5 hours: dramatically less compared to Ethylene Oxide (EtO) process that typical require 48-72 hours on time.

✅ The operational and maintenance cost is almost negligible impacting also the green side with a comparison to classic #steam #sterilization, delivering an impressive -70% energy consumption -70% CO2 emission, -100% water consumption.

✅ Ultimately, it can be a smart & best alternative to steam sterilization to reduce water and energy consumption.

HyPerPure® represents a smart alternative to Ethylene Oxide (EtO) and Gamma Rays, being also the greenest sterilization solution on the market, and helping to reach Carbon Zero target.

Several the advantages to switch from Ethylene Oxide (EtO) or Gamma Rays sterilization:

- Absence of released pollution in the environment (only water and oxygen are released in the air)

- Nor toxic or cancerogenic substances

- Not explosive

- No ATEX certification required

- Easily technology to internalize inside the production plant avoiding external supply management

- Much faster process, with an average of 2-5 hours, versus 48-72 hours of EtO

- 70% footprint reduction (no preconditioning and post-conditioning chambers required and not aeration areas)

Why we could claim that HyPerPure® is the greenest sterilization technology available in Medical Devices and Pharmaceutical markets?

Let’s summarize some quite impressive advantages and “ECO” numbers considering to switch from saturated steam sterilization:

- 0 (ZERO) pollution emissions: H202 creates juts two molecules Water and Oxygen molecules. No other substances are released in the environment

- at the end of the sterilization process

- 100% WATER SAVING

- 70% ENERGY SAVING

- 70% CO2 REDUCTION

In fact, the particular H202 sterilization process is carried out at low temperature requiring a minimum low energy consumption. Therefore there is no thermal energy waste as occurs in hot sterilization processes, such in the case of saturated steam sterilization.

There are practically no liquid discharges towards the installation environment and no water consumption.

For all these reasons, HyPerPure® represents the best option for a company to achieve a ZERO CARBON target.

In conclusion, today you have at your disposal an innovative technology able to sterilize quite a wide range of Medical Devices, like:

- thermolabile catheters,

- plastic syringes,

- packed and ready-to-use syringes,

- masks,

- surgical kits,

- multi-components with electronics (i.e. pace-makers, defibrillators or cochlear implants);

- prothesis for implants for different surgical applications (knee, ankles, elbow, jaw and more).

Product can be packed with multiple protective Tyvek® (or medical paper) layer having the benefit became sterile thanks to the penetration of the H202 delivered by this peculiar cold deep vacuum and zero air sterilization.

The Hydrogen Peroxide sterilization is also perfectly applicable within pharmaceutical industries for instance in the case of empty syringes or cartridges nests sterilization or to sterilize machinery plastic components (like POM-C) or single-use components.

Fig. 3

Fig. 4

De Lama is always available to give to you all technical details and to test the compatibility of every single products in order to identify with you the best & suitable sterilization cycle appropriate to your products.

More info: https://www.delama.it/product/dlvhp-st/