Our unique service allows packaging development to move from design to prototype production to stability testing in a very short period of time.

What used to take months of back and forth designs and testing can now be accomplished in a matter of weeks.

We use virtual 3D-modeling and prototyping to reduce uncertainty and iterative costs, which in turn, lowers your total cost of ownership.

We use virtual 3D-modeling and prototyping to reduce uncertainty and iterative costs, which in turn, lowers your total cost of ownership.

Our i.center service helps packaging designers explore the effects of tool geometry, film types and process conditions, and can predict the protective barrier properties of the final package without running line trials.

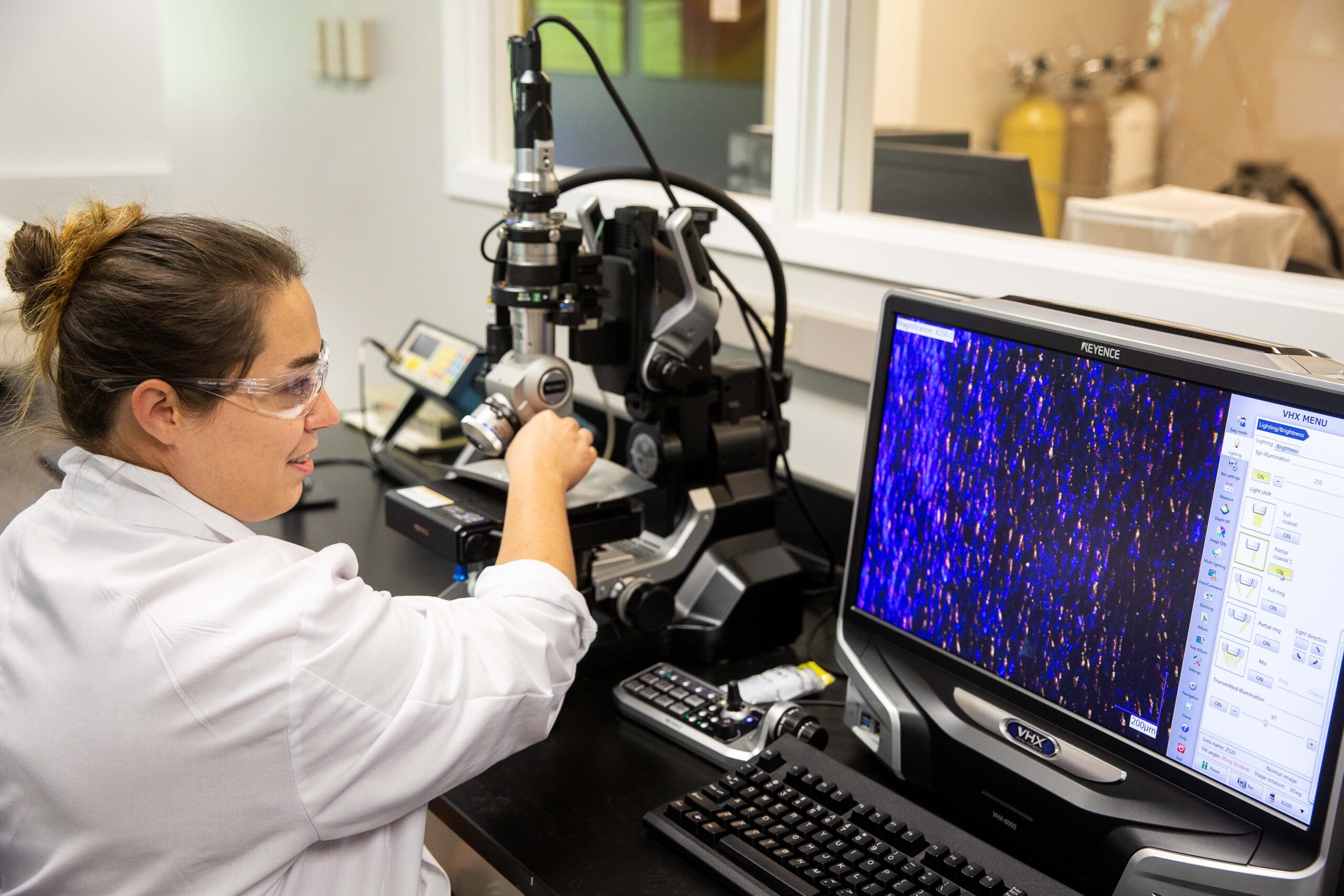

We utilize in-house finite element analysis, CNC automation and state-of-the-art packaging machines allowing for rapid prototyping and product packaging optimization.